2-Pipe VRF Heat Recovery System

Why a 2-Pipe VRF Heat Recovery System Is Your Best Bet

Selecting the right HVAC system for your building is the key to keeping all occupants comfortable in all sorts of hot and cold weather. Our 2-pipe HVAC Heat Recovery system beats the 3-pipe system on all counts, making the 2-pipe system the smart investment. It is simpler in design and less expensive to install. Maintenance costs are also minimal, and the immediate switchover from heating to cooling, and vice versa, means it is easy to comfort people in different rooms if one requires heat while the other needs air conditioning.

Who Benefits? The Question Is, Who Doesn’t?

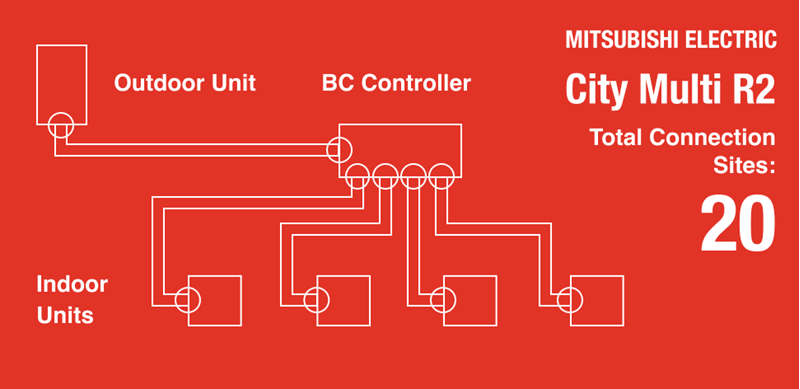

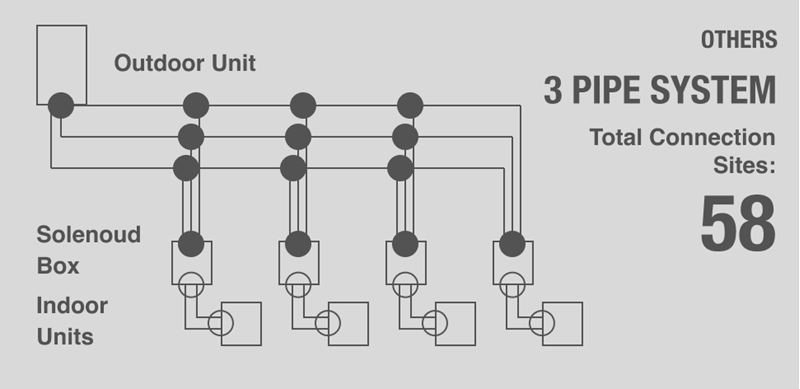

The secret of the 2-pipe lies in the BC Controller which allows the outdoor unit to deliver 2-phase refrigerant for simultaneous heating and cooling. This straightforward system has significantly improved upon 3-pipe technology where occupants waited 4-6 minutes for a switch between heat and cool air. And from developers to contractors, all involved can appreciate the system for its simplicity.

2-Pipe 3-Pipe VRF Heat Recovery System

| 2-Pipe HVAC System |

3-Pipe HVAC System |

|

| Lower labour and material costs | ||

| Faster installation times | ||

| Lower maintenance costs | ||

| Immediate switchover from heating to cooling, and vice versa |

How It Works

2-pipe VRF has a liquid/gas separator with expansion valves that allow the unit to deliver accessible 2-phase refrigerant for simultaneous heating and cooling.

Why Mitsubishi Electric?

- +100 years of experience

- Canadian VRF experience of +20 years

- Made for the Canadian climate

- Superior thermal comfort

- Exceptional application and engineering support

- Expert training and technical support

Benefits of a 2-Pipe VRF Heat-Recovery System

For Builders

and Developers

Two pipes mean fewer connection sites for joints and electrical parts. In turn, this reduces the installation time and overall labour and materials required, therefore creating significant cost-savings. Plus, lower maintenance costs add to the bottom line. Superior thermal comfort is also provided while the streamlined system makes it easier to implement changes in the future.

For Homeowners

and Occupants

The Canadian climate has very distinct seasons. Frequent weather swings and temperature fluctuations can be uncomfortable for building occupants and require sudden changes to the thermal mode. Only the 2-pipe VRF Heat Recovery system switches from heating to cooling and vice versa immediately, while the 3-pipe system takes four to six minutes.

For Architects

and Engineers

The straightforward layout makes it easy to design and comprehend the VRF drawings, meaning it’s easier for architects and engineers to understand the system and lay out a job. Less piping also means a cleaner design and increase in space available.

For Contractors

Fewer piping connections mean less copper and materials are required, which saves installation time and improves the bottom line. Alterations and additions to existing systems are also made easier with the 2-pipe VRF Heat Recovery system. Individual systems can be worked on while the rest of the system is still in service.

Condo Case Study

In a high-rise multi-unit project in downtown Toronto featuring Mitsubishi Electric’s 2-pipe VRF Heat Recovery system, the developer was able to save on materials, time and labour. Had they utilized a 3-pipe VRF Heat Recovery system, then they would have used:

|

~7x MORE branch boxes |

2.3x MORE branch boxes |

|

1.2x MORE isolation valves |

1.5x MORE isolation valves |